…as Michael Myers moved stealthily through the dim malthouse, unconcerned about the Thunder and Lightning around him, plotting his next move…

No, we haven’t confused our holidays and we’re not intro-ing another Halloween-themed blog (though the sheer convenience of having a malthouse manager named Michael Myers makes it tempting), but December did bring lots of Thunder and Lightning to the malthouse, it just did so in the form of…barley.

If you’ve been following our winter barley saga, this is the episode you’ve been waiting for! How does it all end??

For those of you just joining…here’s the 15-second version: Thunder and Lightning are two fall-planted barley varieties, a rarity in Colorado where barley is typically spring-planted. We’re trialing them as part of our attempt to be more resilient in a changing climate. We’ve never grown them before and it’s been a wild ride, including nearly losing both crops to hail, but despite the odds, they rallied, enough to harvest some grain and so…we malted our first batches!

And, as this entire, drama-filled experiment has been, the malting process was…yet another wild ride. A big, stormy, soggy Thunder-and-Lightning filled adventure.

Thunder was our first batch. We had enough of it to do two batches, so, we figured, if we screwed one up, we could always run another. This is the sort of excellent thinking that frequently saves our rear-ends, because naturally, we proceeded to immediately screw up the first batch.

When Thunder went into the steep tank, we discovered it had an extreme water sensitivity that hadn’t shown up in our previous tests. The water uptake on it was faster than any batch we’ve ever seen. Much faster. The barley sucked up water rapidly, swelled to the point of nearly popping out of the manhole of the tank and, essentially, drowned itself. When we realized what was happening, we quickly transferred it out and into the drums, but in malting, steeping is perhaps the most impactful part of the process in terms of creating a high-quality product and if you don’t get it right, it’s hard to recover.

The barley didn’t recover. It was stunted and unhappy, so we kilned it dry and gave it to the Olander Farm cows as an early Christmas present. The cows were thrilled. The malthouse staff, less so.

The second batch came out much better. We knew the shenanigans that Thunder was pulling now, so we moved much faster. We reduced the first steep time way down, we reduced the dry steep time way down, we reduced the second steep down, and then transferred it as fast as possible.

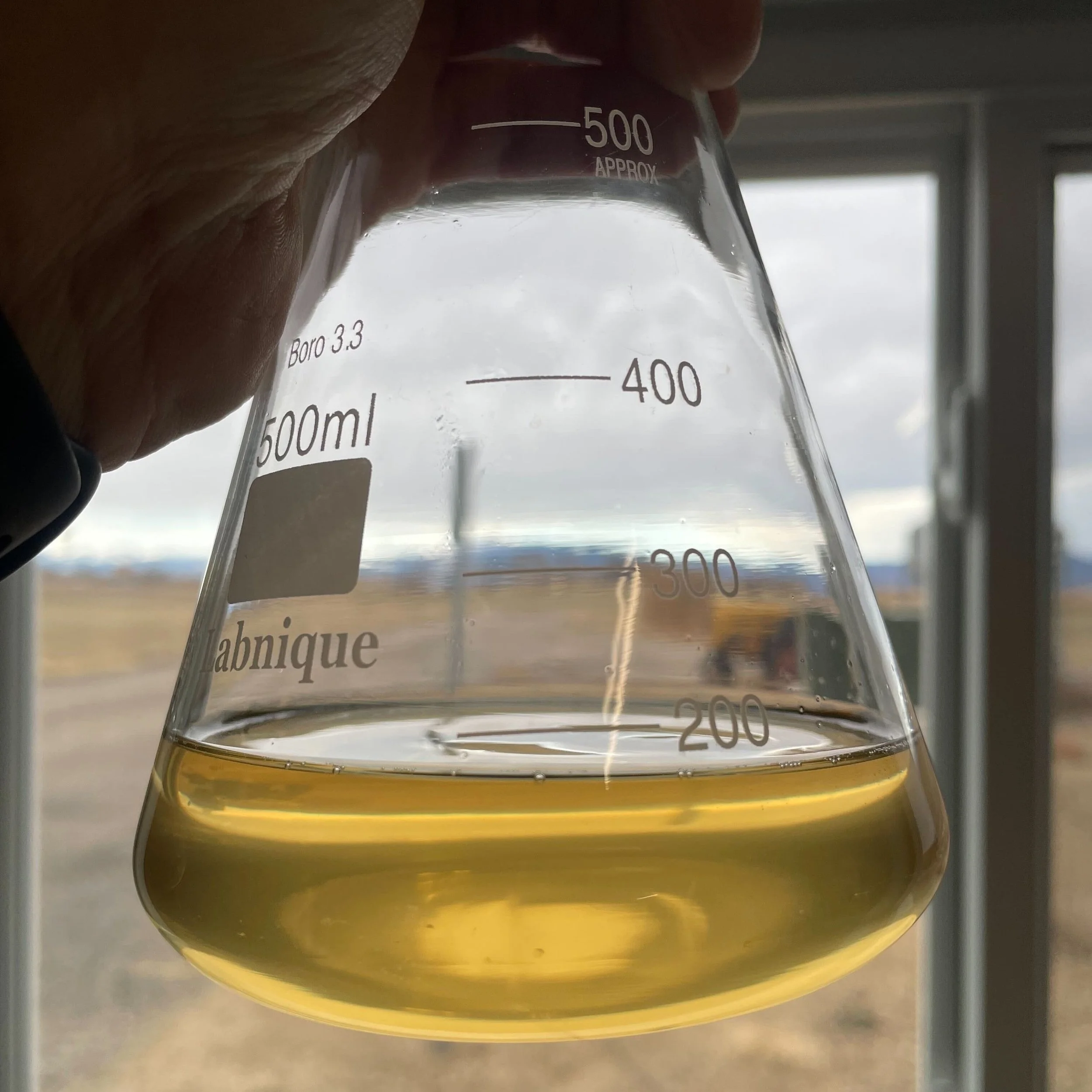

It worked beautifully. The kilning went without a hitch and the end product is gorgeous. We just got the specs back on it and it gives every indication that it’s going to be a fantastic malt: it has high extract, high friability, and the protein is right on the money.

But does it make good beer??

Well, you’ll have to be the ones to let us know! We now have 18,000 lbs bagged and ready to roll out the door. If you’d like to be one of the first to give Thunder Pilsner a try, give our sales team a shout! We can’t wait to see what comes of it!

And what about that Lightning?

Have we mentioned that nothing is ever easy?

Since they are essentially sister varieties, we anticipated the same behavior. We were ready with our timers and our hoses and our tank. We would steep it quickly and move it efficiently.

So naturally, it pulled the completely opposite stunt.

Lightning required more water and longer steep times. It didn’t show the same vigorous water uptake and didn’t need to be transferred as quickly.

Just goes to show that processing new barley varieties has a rather….steep…learning curve.

The jury is still out on Lightning. It’s in the drums as we blog and then we’ll send it off for testing.

In the meantime, if you’re looking for more good things, remember that we’ve run two other experimental batches this year! Our first chit malt was just released last month, and our new Munich Wheat malt just got a shout-out in this article by The Colorado Sun on brewers and distillers using local grains.